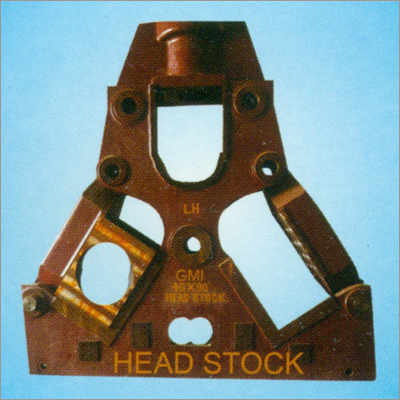

Sugar Mill Machinery Parts Headstock

500000.00 - 1000000.00 INR/Piece

Product Details:

- Dimension (L*W*H) 1200mm x 650mm x 700mm

- Shape Rectangular

- Coating Type Epoxy Coated

- Application Sugar Mill Machinery

- Components Headstock Body, Mounting Flange, Bearing Support

- Hole Size 32 mm

- Weight Approx. 800 kg

- Click to View more

X

Sugar Mill Machinery Parts Headstock Price And Quantity

- 1 , , Piece

- 500000.00 - 1000000.00 INR/Piece

Sugar Mill Machinery Parts Headstock Product Specifications

- Base Mounted

- Industrial Machinery

- Machined

- 10-15 Millimeter (mm)

- Approx. 800 kg

- Epoxy Coated

- Up to 50 Tons

- Stainless Steel, Steel, Aluminum

- Anti-corrosive Painting

- Sugar Mill Machinery

- 0.02 mm

- Rectangular

- 1200mm x 650mm x 700mm

- 32 mm

- Headstock Body, Mounting Flange, Bearing Support

- Casting and Machining

Sugar Mill Machinery Parts Headstock Trade Information

- Cash on Delivery (COD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 10-12 Week

- Wooden Box

- Western Europe, Asia, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America

- All India

Product Description

A cast steel headstock is a type of sugar mill machinery part used in the extraction of juice from sugarcane. The headstock is the main supporting structure for the equipment used to extract juice from the sugarcane, such as the Grooved Roller Pressure Feeder (GRPF).

The headstock is typically manufactured using cast steel, a strong and durable material that is resistant to wear and corrosion. It consists of several components, including the bearing housing, roller shaft, coupling, and gear reducer. The bearing housing supports the roller shaft and provides a bearing surface for the rollers to rotate. The coupling connects the roller shaft to the gear reducer, which drives the rollers.

The headstock must be designed to withstand the high loads and stresses generated during the crushing process. It must also be manufactured to precise tolerances to ensure smooth and efficient operation of the equipment. The use of cast steel allows the headstock to withstand these demands and provide a reliable and long-lasting support structure for the equipment.

Overall, the cast steel headstock is a critical component in the sugar mill machinery used for extracting juice from sugarcane. It is designed to provide a reliable and durable mounting structure for the equipment, which is essential for efficient sugar production. The use of cast steel ensures that the headstock can withstand the high loads and stresses of the sugar production process and provide long-lasting service.

Robust Construction and Superior Materials

Our headstock components are manufactured from high-grade stainless steel, steel, and aluminum, ensuring longevity even under demanding conditions. The anti-corrosive surface treatment and epoxy coating safeguard against harsh industrial environments, while precise machining guarantees reliable integration within sugar mill systems.

Customizable Solutions for Industrial Demands

We offer customization to accommodate specific operational needs and dimensions, providing parts precisely tailored to your sugar mill machinery. Each headstock is designed with critical components such as mounting flange and bearing support, optimizing functionality and ease of installation.

FAQs of Sugar Mill Machinery Parts Headstock:

Q: How is the headstock component manufactured for sugar mill machinery?

A: The headstock is produced using advanced casting and machining processes, which ensure both its structural integrity and precision. Each part is treated with anti-corrosive painting and epoxy coating to enhance resistance against wear and corrosion.Q: What materials are used in the construction of these headstock machinery parts?

A: Our headstock parts are crafted from high-quality stainless steel, steel, and aluminum, which are selected for their durability, excellent machinability, and capacity to withstand industrial stresses.Q: When should I consider customization for my sugar mill headstock?

A: Customization is recommended when your machinery specifications or operational requirements differ from standard dimensions or features. We offer tailored solutions to fit unique needs in terms of size, thickness, or component configuration.Q: Where are these sugar mill machinery parts produced and exported from?

A: All headstock components are manufactured and exported from India by an experienced manufacturer catering to global industrial markets.Q: What is the process for ensuring high tolerance and weight capacity in the headstock?

A: Each part undergoes precision machining to achieve a tight tolerance of 0.02 mm. The robust design and material selection enable the headstock to handle loads of up to 50 tons while maintaining stability and accuracy.Q: How can these parts benefit my industrial sugar mill operation?

A: The headstock delivers exceptional wear and corrosion resistance, supports heavy capacities, and maintains reliability over long service periods, reducing maintenance and increasing overall operational efficiency.Q: What is the recommended usage and application for this product?

A: Specifically engineered for industrial sugar mill machinery, the headstock is ideal for critical components such as the headstock body, mounting flange, and bearing support, ensuring optimal mechanical performance and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Parts' category

|

GANESH METAL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |