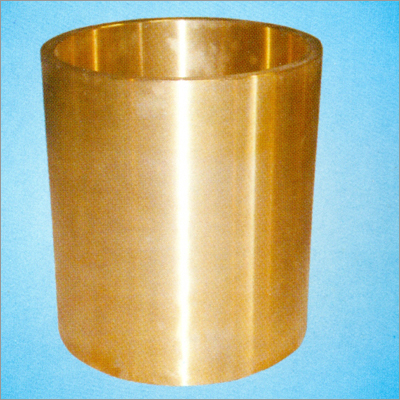

Grooved Liner

150000.00 - 200000.00 INR/Piece

Product Details:

- Surface Finishing Smooth grooved finish

- Dimension (L*W*H) Customizable sizes

- Mount Type Bolt-on or welded

- Usage Used as liner in various industrial equipment

- Components Single or multi-part construction

- Coating Type Protective paint or custom as needed

- Hole Size Customizable

- Click to View more

X

Grooved Liner Price And Quantity

- 150000.00 - 200000.00 INR/Piece

- 1 , , Piece

Grooved Liner Product Specifications

- Customizable sizes

- Smooth grooved finish

- 0.05 mm

- Anti-corrosive coating

- Bolt-on or welded

- Protective paint or custom as needed

- Customizable

- Used as liner in various industrial equipment

- Single or multi-part construction

- Suitable for mechanical, mining, and processing industries

- Grooved machining

- Rectangular or as required

- Other

- Varies with specification

Grooved Liner Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 4 Week

- Wooden Box

- All India

Product Description

A grooved liner is a type of liner used in various industrial applications to improve the performance of pipes and other components. A grooved liner consists of a cylindrical sleeve with a series of grooves or channels along its length, designed to improve flow characteristics and reduce turbulence.

Grooved liners are often used in piping systems to reduce pressure drop, improve flow efficiency, and prevent clogging and other flow-related problems. They may also be used in other applications, such as pump casings, impellers, and other components where improved flow characteristics are desired.

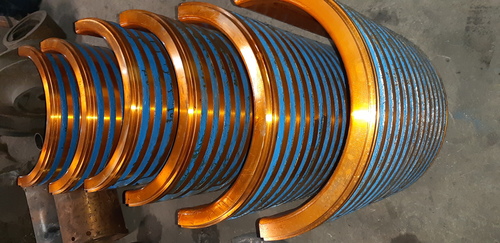

The grooves or channels in a grooved liner may be straight or helical, depending on the application and the desired flow characteristics. They may be of varying depth and spacing, and they may be arranged in a variety of patterns to achieve different flow effects.

Grooved liners may be made of various materials, such as rubber, plastics, or metals, depending on the application and operating conditions. They are typically designed to be easily installed and removed, and they may include features such as flanges, couplings, or other mechanisms to facilitate connection to other components.

Overall, grooved liners are a versatile and effective solution for improving the flow characteristics of pipes and other components in various industrial applications. They can help to reduce pressure drop, improve efficiency, and prevent clogging and other flow-related problems, improving the overall performance and reliability of the system.

Built for Tough Industrial Applications

Grooved Liners offer unparalleled strength and protection in aggressive environments such as mining, mechanical, and processing industries. Built with enhanced wear and corrosion resistance, their design ensures a longer operational life even under the most challenging conditions. With custom groove design, hole size, and dimensions available, these liners fit seamlessly into complex equipment, fulfilling exacting industry requirements.

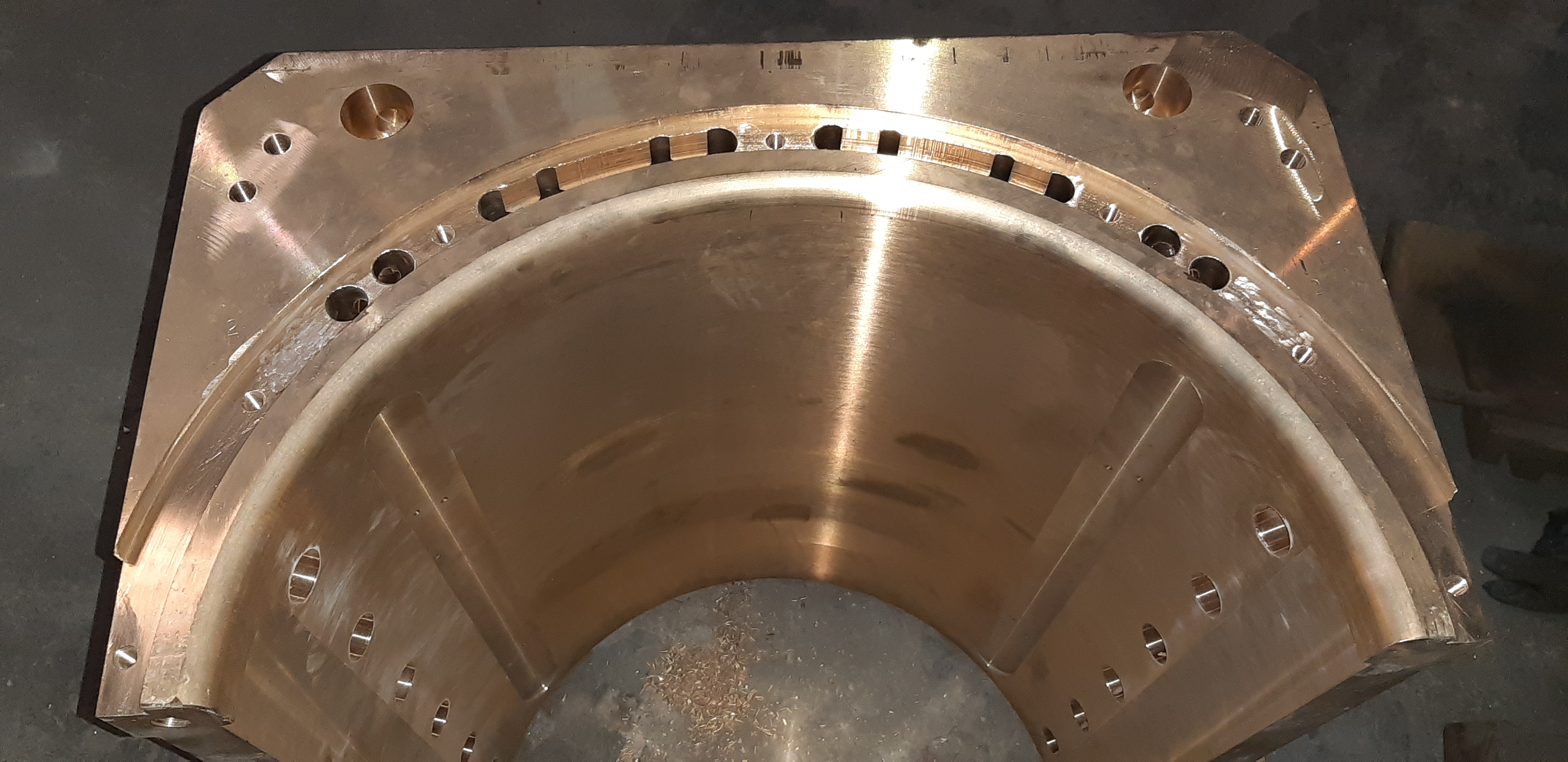

Customizable for Maximum Flexibility

Every Grooved Liner can be tailored according to your specific application needs. Available in single or multi-part configurations, users can specify groove pattern, shape, coating type, and surface finish. Their bolt-on or welded mounting options and easy installation features allow adaptability during equipment upgrades or maintenance, reducing downtime and maximizing efficiency.

FAQs of Grooved Liner:

Q: How is the grooved liner installed on industrial equipment?

A: The grooved liner is designed for easy installation, featuring both bolt-on and welded mounting options. Simply align the liner with the equipments mounting points and secure it as specified in the user guide. Custom hole sizes and shapes ensure a precise fit.Q: What benefits does the grooved design offer?

A: The parallel or cross-groove design enhances abrasion resistance, promotes even wear distribution, and improves debris channeling. This engineered structure prolongs the liners operational life, supporting reliable performance in demanding environments.Q: When should I consider replacing my liner?

A: Replacement is typically recommended when visible wear or reduced protection is noticed. Thanks to their enhanced wear resistance and corrosion-proof construction, grooved liners have a longer service lifespan, reducing the frequency of replacements.Q: Where can grooved liners be used?

A: Grooved liners are suitable for a variety of industries, including mining, mechanical, and processing sectors. They are commonly installed in equipment exposed to abrasive materials or corrosive environments, wherever extended durability and protection are required.Q: What is the process of customizing a grooved liner?

A: Customization involves providing your required drawings or specifications, including groove pattern, depth, dimensions, shape, and coating type. The manufacturer then uses precision grooved machining to produce liners that meet your exact needs, within tight tolerances of 0.05 mm.Q: How does the grooved liner withstand high-temperature and corrosive conditions?

A: Constructed with materials rated for up to 300C and a minimum surface hardness of 50 HRC, the liner is finished with an anti-corrosive coating and protective paint, ensuring reliable performance in aggressive environments.Q: What are the main benefits of using these grooved liners?

A: Key benefits include enhanced wear and corrosion resistance, extended equipment and liner lifespan, customizable designs, easy installation and replacement, and suitability for a broad range of demanding industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Parts' category

|

GANESH METAL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |