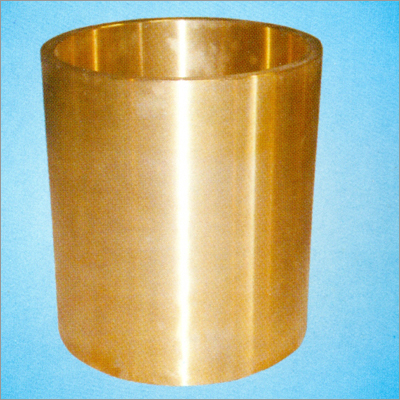

Bronze Liner

50000.00 - 150000.00 INR/Piece

Product Details:

- Surface Finishing Smooth, Mirror-like finish

- Hole Size Customizable as per shaft size

- Weight Varies by dimension

- Dimension (L*W*H) Customized as per requirement

- Coating Type Uncoated or as per requirement

- Shape Cylindrical/Custom

- Mount Type Press Fit/Slide Fit

- Click to View more

X

Bronze Liner Price And Quantity

- 1 , , Piece

- 50000.00 - 150000.00 INR/Piece

Bronze Liner Product Specifications

- Varies by dimension

- Customizable as per shaft size

- Uncoated or as per requirement

- Customized as per requirement

- Bronze Body

- Industrial Machinery Support

- Cylindrical/Custom

- Press Fit/Slide Fit

- Bearings, Bushings, Heavy Machinery

- Smooth, Mirror-like finish

- Polished

- Precision Casting and CNC Machined

- 0.01 mm

- High-quality Bronze Alloy

- N/A (Liner specific)

Bronze Liner Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 2-3 Week

- Wooden Box

- All India

Product Description

A bronze liner is a type of bearing or bushing made from bronze material that is used to reduce friction between two metal surfaces. Bronze liners are commonly used in various types of machinery, including pumps, compressors, engines, and gearboxes.

Bronze is a popular material for liner bearings due to its excellent wear resistance, high strength, and good corrosion resistance. It can also withstand high temperatures and high-pressure conditions, making it ideal for use in heavy-duty applications.

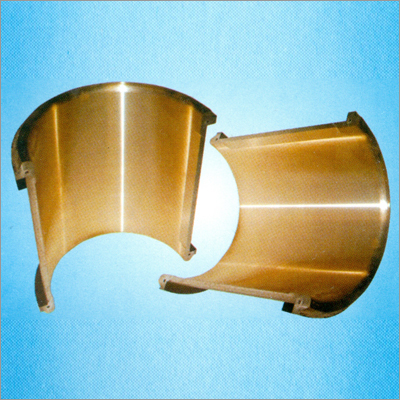

Bronze liners may be used in a variety of configurations, including sleeve bearings, flanged bearings, and thrust bearings. They are typically manufactured to precise tolerances to ensure proper fit and alignment with the mating components.

Overall, bronze liners are a critical component in many industrial applications where low friction, high strength, and durability are required. They provide a reliable and long-lasting bearing surface that can reduce wear and improve the efficiency of machinery. Their versatility and excellent performance make them a popular choice for a wide range of applications in various industries.

High-Grade Material and Superior Performance

Constructed from premium tin bronze alloy, this liner delivers reliable strength and resilience. Its high-grade material selection ensures optimal thermal and mechanical performance under demanding industrial environments. Precision engineering guarantees excellent machinability and a mirror-like finish, suitable for rigorous applications.

Customization for Versatile Applications

Whether for standard or tailored specifications, this bronze liner supports a wide range of industrial needs, from heavy machinery bearings to custom bushings. Dimensions, shapes, and even hole sizes are fully adaptable, ensuring a precise fit and seamless integration into existing assemblies.

Manufacturing Excellence and Export Capability

Manufactured in India using precision casting and CNC processes, each liner meets strict international standards like IS 318 and ASTM B505. With a polished finish and customizable options, these liners are exported globally, renowned for their quality and adaptable engineering.

FAQs of Bronze Liner:

Q: How is the Bronze Liner manufactured to ensure high quality?

A: The Bronze Liner is produced using a combination of precision casting and CNC machining, resulting in a highly accurate and mirror-smooth finish. Each liner undergoes stringent quality control to meet IS 318 and ASTM B505 standards.Q: What are the primary industrial uses of the Bronze Liner?

A: This liner is widely used in industrial machinery, specifically in bearings, bushings, and heavy equipment components, where durability and resistance to high temperatures are essential.Q: Can the dimensions and hole sizes of the Bronze Liner be customized?

A: Yes, all dimensions including length, width, height, and hole sizes can be customized to meet specific requirements or drawings, ensuring a perfect fit for your application.Q: When can I expect delivery after placing an order for the Bronze Liner?

A: The typical lead time for manufacturing and delivery is 2 to 4 weeks, depending on the complexity and customization needed.Q: Where are these Bronze Liners manufactured and exported from?

A: These liners are manufactured in India, adhering to international standards, and are exported globally for various industrial applications.Q: What benefits does the Bronze Liner offer over other materials?

A: Compared to other materials, this bronze liner provides excellent machinability, superior resistance to wear and heat (up to 300C), and outstanding dimensional tolerance, making it ideal for precision applications.Q: How does the precision tolerance of 0.01 mm impact performance?

A: The strict tolerance ensures a secure and accurate fit, reducing vibration, enhancing operational efficiency, and prolonging the lifespan of machinery components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Parts' category

|

GANESH METAL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |