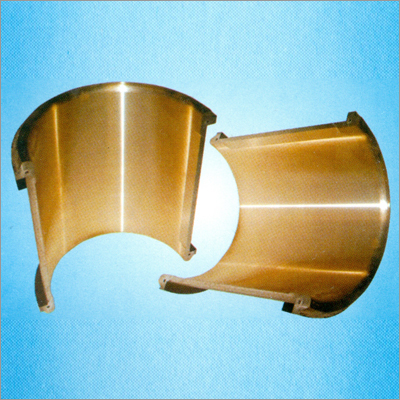

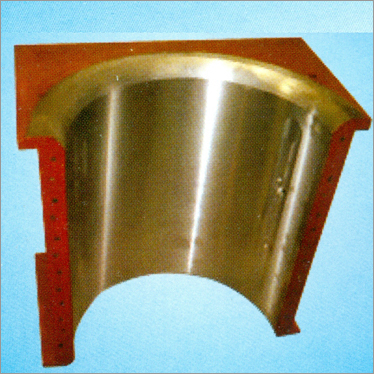

White Metals Bearing

250000.00 - 300000.00 INR/Piece

Product Details:

- Surface Finishing Fine Smooth Finish

- Hole Size Custom / As per shaft size

- Dimension (L*W*H) Custom / As per requirement

- Usage Rotating Equipment

- Shape Cylindrical / Half Cylindrical

- Coating Type Anti-corrosion Coating

- Application Industrial Machinery, Turbine, Pump, Engine

- Click to View more

X

White Metals Bearing Price And Quantity

- 250000.00 - 300000.00 INR/Piece

- 1 , , Piece

White Metals Bearing Product Specifications

- Custom / As per requirement

- Custom / As per shaft size

- Fine Smooth Finish

- Cylindrical / Half Cylindrical

- Anti-corrosion Coating

- Rotating Equipment

- Industrial Machinery, Turbine, Pump, Engine

- 0.02 mm

- Press Fit / Slide Fit

- Shell, Babbitt Lining

- CNC Punching, CNC Bending

- Heavy Load Bearing

- White Metal (Babbitt Alloy)

- Polished

- Depends on size and application

White Metals Bearing Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 4 Week

- Wooden Box

- All India

Product Description

White metal bearings are a type of bearing commonly used in industrial machinery to support rotating shafts. White metal bearings are typically made of a soft alloy containing tin, lead, and antimony, which has a low melting point and can conform to the shape of the shaft.

White metal bearings are typically used in applications where high loads and low speeds are present, such as in large-scale machinery used in the mining, steel, and cement industries. They are designed to provide a secure and reliable bearing surface for the rotating shaft, reducing friction and wear and ensuring smooth and efficient operation.

White metal bearings may be designed for a specific application, such as high-load or high-speed applications, or they may be more general-purpose and suitable for a wide range of applications. They may include features such as oil grooves or other mechanisms to improve their performance and longevity.

Overall, white metal bearings are a critical component in many industrial machinery applications. They provide a soft, conformable bearing surface that can support high loads and reduce friction and wear, ensuring smooth and efficient operation. They are typically durable, long-lasting, and resistant to corrosion and other types of damage, making them ideal for use in various industrial applications.

Exceptional Durability and Reliability

Engineered with a Babbitt lining and polished surface, these bearings offer superb wear resistance and a long service life. Their ability to withstand high operating temperatures and heavy loads makes them a top choice for demanding industrial environments.

Precision Engineering with Customization

Utilizing CNC punching and bending processes, every bearing is manufactured with exceptional accuracy, maintaining a tolerance of 0.02 mm. Dimensions, hole sizes, and weight are fully customizable as per application requirements and shaft specifications.

Optimized for Rotating Equipment

Designed for high precision and low friction coefficient, these bearings are ideally suited for rotating components in machinery, turbines, and pumps. Their fine finish and anti-corrosion coating ensure smooth and efficient performance even under rigorous operational conditions.

FAQs of White Metals Bearing:

Q: How does the white metals bearing benefit high precision applications?

A: With its precision CNC manufacturing, fine surface finishing, and low friction coefficient, the white metals bearing ensures accurate movement and minimal wear, which is vital for high precision machinery.Q: What is the recommended lubrication requirement for these bearings?

A: It is essential to use appropriate lubrication during operation to maintain low friction, enhance wear resistance, and prolong the service life of the bearing.Q: Where can these bearings be used?

A: These versatile bearings are suitable for turbines, pumps, engines, and a variety of rotating equipment within industrial machinery applications.Q: What is the making process for these bearings?

A: White metals bearings are produced using advanced CNC punching and CNC bending techniques to achieve high dimensional accuracy and consistent quality.Q: When should a custom dimension or hole size be specified?

A: Custom dimensions and hole sizes should be provided when the bearing must fit unique shaft sizes or machinery layouts, ensuring optimal performance and compatibility.Q: What are the packaging options available for shipping?

A: Depending on quantity and customer preference, bearings are delivered in durable wooden boxes or cartons to guarantee safe transport and storage.Q: How does the anti-corrosion coating enhance bearing benefit?

A: The anti-corrosion coating protects the bearing from environmental damage, ensuring longevity and reliable operation even in demanding or harsh conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Metal Parts' category

|

GANESH METAL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |