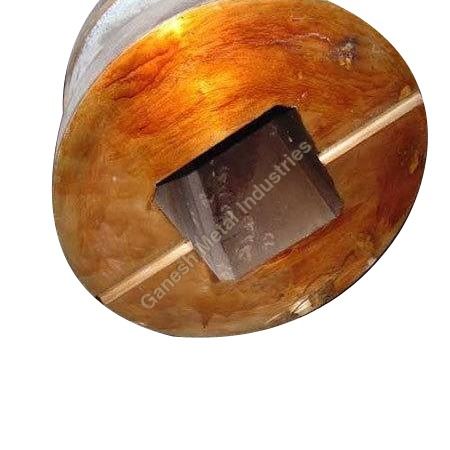

Fibrizer hammer

6000 INR/Piece

Product Details:

- Features High Wear Resistance, Easy to Install

- Size Standard

- Shape Rectangular

- Usage & Applications Sugar Mill Fibrizer

- Surface Finish Polished

- Capacity High Impact Resistance

- Drive Type Direct Mount

- Click to View more

X

Fibrizer hammer Price And Quantity

- 10 Piece

- 5000.00 - 7000.00 INR/Piece

- 6000 INR/Piece

Fibrizer hammer Product Specifications

- Machine Spare Part

- Rectangular

- Standard

- 310mm x 80mm x 30mm (approx)

- Forged Engineering

- 25 Kilograms (kg)

- Mechanical

- High Wear Resistance, Easy to Install

- Heat Treated

- Low

- Metallic Grey

- Mild Steel

- Direct Mount

- High Impact Resistance

- Polished

- Sugar Mill Fibrizer

Fibrizer hammer Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 4 Week

- All India

Product Description

Fibrizer hammer enables the prepared cane to be crushed in between the mill's rollers to extract juice. It is designed for shredding sugarcane into fibres and open cells. In addition to this, our offering has swappable tips and specially crafted rotor discs with three or four integrated arms prevent failure from shocks. Our offering is ideal after the cane has been levelled and to prepare the cane in sugar industry. Fibrizer hammer works well in preparation and operation. This product crushes sugarcane after a series of revolving cane knives and a milling procedure. It performs the majority of the work of fibrizing the chopped cane.

Optimized Impact Strength and Corrosion Resistance

Designed for heavy-duty crushing tasks, the Fibrizer hammer boasts superior impact strength and a specialized corrosion-resistant finish. These features ensure longevity and reliable performance, even in harsh sugar mill environments where durability and efficiency are paramount.

Simple Installation and Compatibility

The hammer is crafted with a bolt-on design, allowing for quick and straightforward assembly. Its standard size and direct mount drive make it compatible with a wide range of Fibrizer models, minimizing downtime and maximizing operational output for manufacturers.

Advanced Manufacturing and Surface Technology

Produced using drop forging and advanced surface hardening techniques, the Fibrizer hammer achieves high hardness and wear resistance. The heat-treated, polished surface combined with forged engineering elevates its strength and performance, making it suitable for continuous industrial use.

FAQs of Fibrizer hammer:

Q: How does the Fibrizer hammer optimize heavy-duty crushing performance in sugar mills?

A: The hammer is engineered with high-impact strength, drop-forged mild steel, and a hardness rating of 5256 HRC, making it ideal for demanding crushing operations. Its robust construction and surface treatment also contribute to consistent and efficient performance.Q: What maintenance is required for the Fibrizer hammer during its operational life?

A: Due to its surface hardening and corrosion-resistant finish, the hammer requires minimal maintenance. Periodic inspections and standard cleaning procedures help to ensure longevity and effective operation in sugar mill environments.Q: When should the Fibrizer hammer be replaced or inspected for wear?

A: Regular inspections are recommended, especially after intensive production cycles. Replacement is advised if signs of excessive wear, decreased impact resistance, or surface damage are observed, helping to maintain optimal crushing efficiency.Q: Where is the Fibrizer hammer typically installed and used?

A: The hammer is primarily used in sugar mill Fibrizer equipment, installed using a straightforward bolt-on design. Its compatibility with various models ensures it suits a wide range of industrial crushing applications.Q: What manufacturing process is used to ensure the hammers high hardness and wear resistance?

A: Fibrizer hammers are manufactured using drop forging combined with surface hardening and heat treatment. These processes yield a high level of hardness and wear resistance essential for heavy-duty use.Q: How does the bolt-on design benefit users during installation and maintenance?

A: The bolt-on design facilitates easy installation and removal, reducing downtime during maintenance and replacements. This user-friendly feature supports quick assembly, making routine handling more efficient for operators.Q: What are the key benefits of choosing this Fibrizer hammer for your sugar mill?

A: Key benefits include high impact resistance, long operational lifespan due to corrosion protection, low noise operation, compatibility with various models, and easy installation. These qualities streamline crushing operations and optimize productivity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Sugar Mill Machine Parts' category

|

GANESH METAL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |